Vacuum baking equipment

-

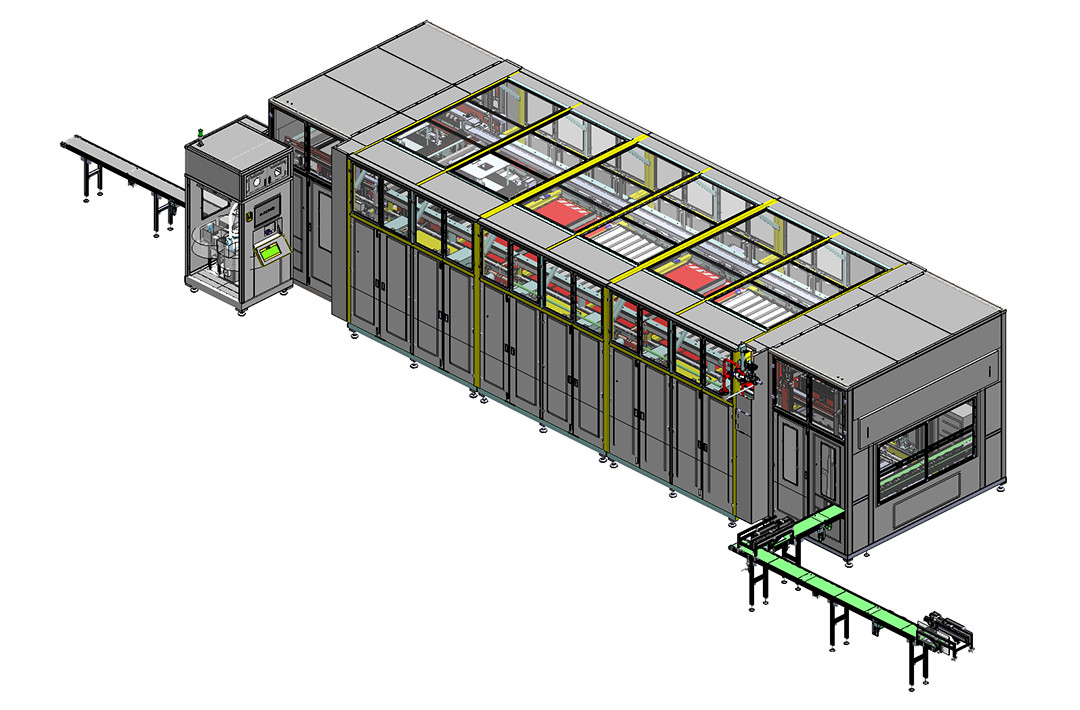

Fully automatic high-temperature standing & aging furnace

Fully automatic high-temperature aging of battery after electrolyte injection

Improve battery capacity consistency (temperature consistency makes electrolyte be fully infiltrated)

Improve high-temperature standing efficiency, decreased from 24 hours to 6 hours

Battery aging data is traceable.

-

Vacuum baking monomer furnace series

Each chamber of monomer furnace can be heated and vacuumized separately to bake the battery and operation of each chamber does not affect each other, Flow of fixture trolley for RGV dispatching and carrying battery between chamber and loading/ unloading can realize on-line battery baking. This equipment is divided into five parts, feeding group tray, RGV dispatching system, vacuum baking, unloading & dismantling tray cooling, maintenance & caching.

-

Vacuum baking tunnel furnace series

Tunnel furnace chamber is arranged in a tunnel type, with compact structure layout, The whole machine includes heating trolley, chamber (atmospheric pressure + vacuum), plate valve (atmospheric pressure + vacuum), ferry line (RGV),maintenance station, loader/ unloader, pipeline and logistics line (tape).