Vacuum baking monomer furnace series

Process flow chart

Equipment characteristics

Chamber and fixture trolley work separately without affecting each other and can lower down the capacity loss in case of fault;

Vacuum leak rate of chamber is within 4 PaL/s, and ultimate vacuum is 1 Pa;

Every layer of hot plate of fixture trolley is controlled separately and it can assure the temperature of hot plate ± 3°C ;

Mirror reflectors covered with heat-insulation cotton outside are distributed inside the chamber and outer wall temperature of chamber is 5°C higher than the room temperature at the most;

Maintenance station is equipped to realize offline maintenance of fixture trolley;

Operate in a closed environment, It only needs to feed dry air in the unloading and cooling areas and no drying room is required, so as to lower down energy consumption;

Cell baking information is associated with OR code and uploaded to MES system.

Equipment application (blade battery)

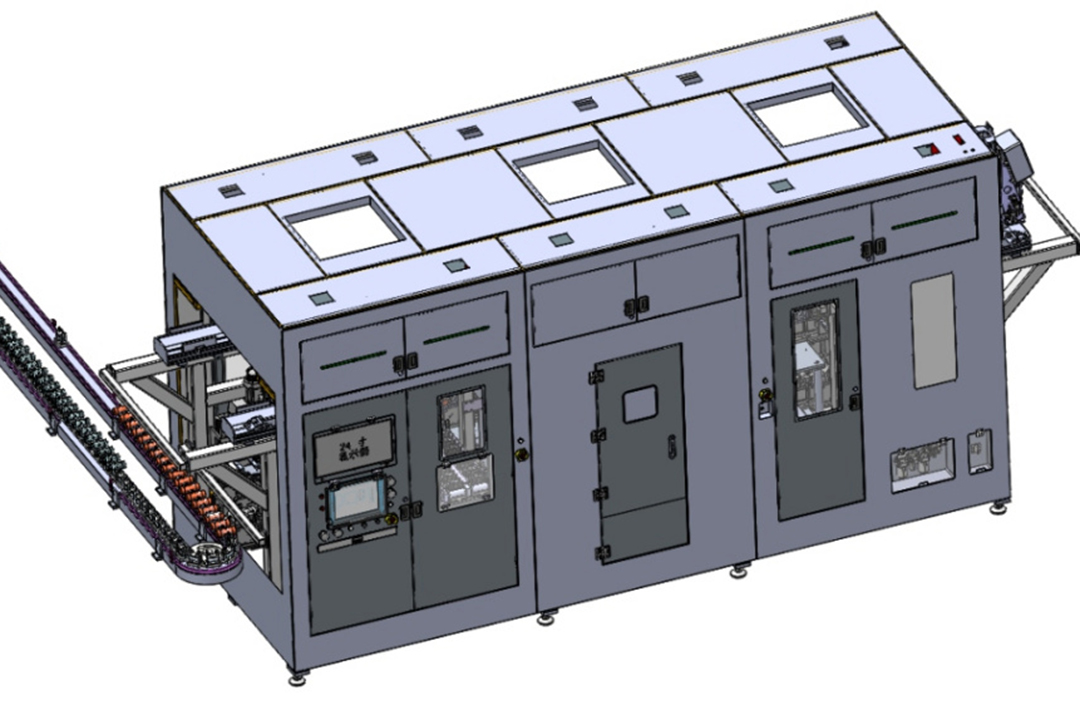

Monomer furnace oven for blade battery

Before loading, scan QR code to reject NG batteries automatically. Moisture battery will be assembled automatically and the whole line is sealed, It only needs to feed dry air in the unloading and cooling areas, so as to ensure dew point and lower down the energy consumption of dry air.

Fixture trolley for blade battery

Heating plate

Drawer-type fixture for multi-layer heating plate; blade battery is placed on the heating plate vertically. Vertical side plate of the fixture can not only locate the battery, but also help to accelerate the battery temperature rise. Battery is bonded with the heating plate and thus can be heated up to the required temperature quickly.

Technical parameters

Equipment dimension: W= 30000 mm; D= 9000 mm; H= 4500 mm

Compatible battery size: L= 150 ~ 650 mm; H= 60 ~ 250 mm; T= 10 ~ 25 mm

Moisture content: < 150 PPM

Process time: 300 ~ 480 min

Equipment eficiency: 30 PPM

Vehicle battery capacity: 700 ~ 800 PCS

Allowable number of vacuum chambers: 6 ~ 12 PCS

Equipment application (large pouch battery)

Monomer furnace oven for large pouch battery

Loading clamp will grab 20 pcs of batteries at one time, to ensure the Takt time of the entire line can exceed 20 ppm. When clamp grabs the batteries, air bag will cause no damage to the battery electrode body.

Fixture trolley for large pouch battery

Heating plate

Drawer-type fixture for multi-layer heating plate; large pouch battery is placed on the heating plate vertically. Vertical side plate of the fixture can not only locate the battery, but also help to accelerate the battery temperature rise. The special-purpose air bag supporting mechanism locates the air bag and helps to realize automatic loading and unloading.

Technical parameters

Equipment dimension: W= 30000 mm; D= 9000 mm; H= 4500 mm

Compatible battery size: L= 150 ~ 650 mm; H= 60 ~ 250 mm; T= 10 ~ 25 mm

Moisture content: < 150 PPM

Process time: 300 ~ 480 min

Equipment eficiency: 30 PPM

Vehicle battery capacity: 700 ~ 800 PCS

Allowable number of vacuum chambers: 6 ~ 12 PCS

Equipment application (square-shell battery)

Monomer furnace oven for square-shell battery

Before loading, scan OR code to reject NG batteries automatically and moist battery. The robot will grab a complete row of batteries for assembly and efficiency of the dispatching system can reach 20 ~ 40 PPM.

Fixture trolley for square-shell

Heating plate

Drawer-type fixture for multi-layer heating plate; square-shell battery is placed on the heating plate vertically. Battery is provided with spacers for location and battery spacing is small, which can increase the space utilization and heat efficiency and improve the capacity of small size battery. Battery is bonded with the heating plate and auxiliary heating are added surrounding it, thus it can be heated up to the required temperature quickly.

Equipment dimension : W=34000mm;D=7200mm;H=3600mm

Compatible battery size : L=100~220mm ; H=60~230mm ;T=20~90mm;

Moisture content : <150PPM

Process time :240~560min

Equipment efficiency:40PPM

Vehicle battery capacity :220~840PCS

Allowable number of vacuum chambers:5~20PCS

Equipment application (cylindrical battery)

Monomer furnace oven for square-shell battery

Single chamber is loaded with a great number of cells. The equipment efficiency is high and compatible with various battery sizes, with convenient and rapid changeover.

Drawer-type fixture for multi-layer heating plate; cylindrical batteries are fixed onto the heating plate vertically via the positioning fixture and side auxiliary heating plate can accelerate the temperature rise of cells.

Technical parameters

Equipment dimension: W= 30000 mm; D= 9000 mm; H= 4500 mm

Compatible battery size: L= 150 ~ 650 mm; H= 60 ~ 250 mm; T= 10 ~ 25 mm

Moisture content: < 150 PPM

Process time: 300 ~ 480 min

Equipment eficiency: 30 PPM

Vehicle battery capacity: 700 ~ 800 PCS

Allowable number of vacuum chambers: 6 ~ 12 PCS

测量仪.png)