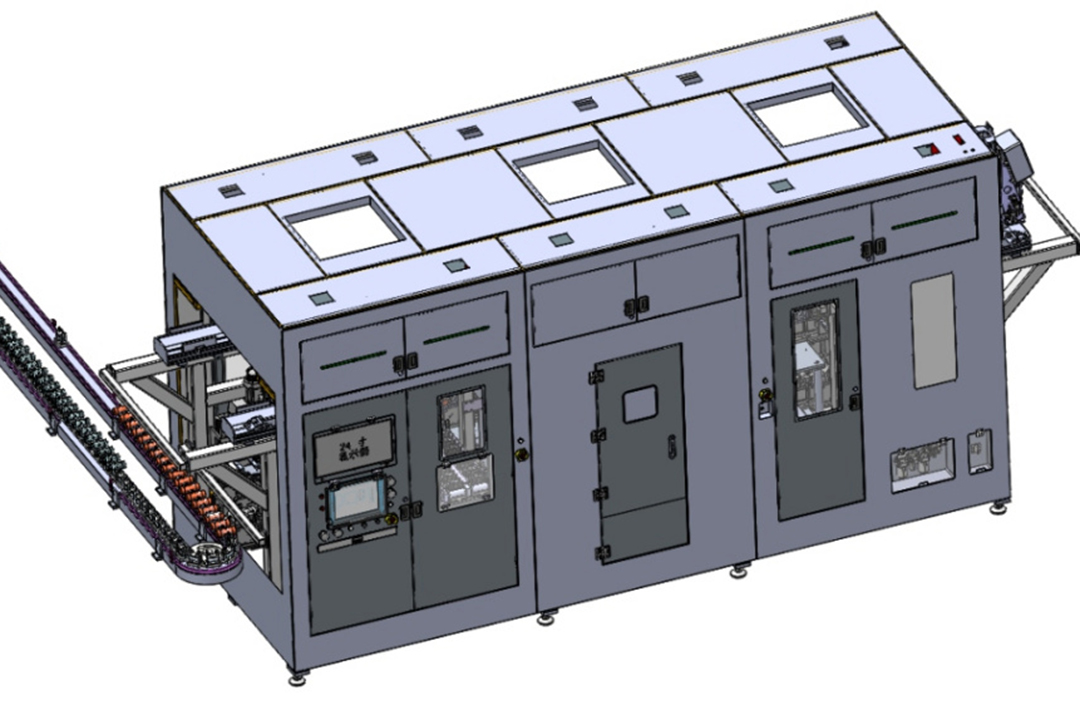

Semi-automatic offline imager

Equipment dimension drawing

Equipment characteristics

Overhang automatic detection function: Image algorithms of software can detect a maximum thickness of 48 layers of cells :

Real-time image enhancement function:

Video navigation function:

Calibration function of fat panel detector: It can achieve dark and bright field calibration for flat panel detector:

Image save function for test results:

Prompt message output function: Calibration function, navigation calibration function;

Imaging effect

Wrinkle detection

Overhang detection

| Name | Indexes |

| Body size | L=1400mm W=1620mm H=1900mm |

| Weight | 2500kg |

| Power | 5kw |

| Detection area | 600mm x 600mm |

| Type of X-ray tube | Closed tube |

| Power of X-ray tube | 75W ( 150KV,500uA ) |

| Flat panel detector | Effective area of detector : 250 x 300mm Imaging matrix : 2500 x 3000mm |

| Axis-Z travel of detector | 500mm |

| Magnification | 1.5~12.5x(system magnification 1000x ) |

| Number of effective layers detected | ≤48 layers |

| X-ray leakage | ≤1.0μSv/hr |

| IPC | Dual core CPU, 4G memory, 500G hard disk, equivalent or higher configuration |

| Display | 21.5 inches, equivalent or higher configuration |

| UPS | Voltage fluctuation ≤±2% |

| Ambient temperature | <50°C |

| Ambient humidity | <85%,no condensation |

| Power supply | 220V/50Hz |

| Feeding mode | Manual loading and unloading |

Write your message here and send it to us

测量仪.png)