X-ray imaging inspection equipment

-

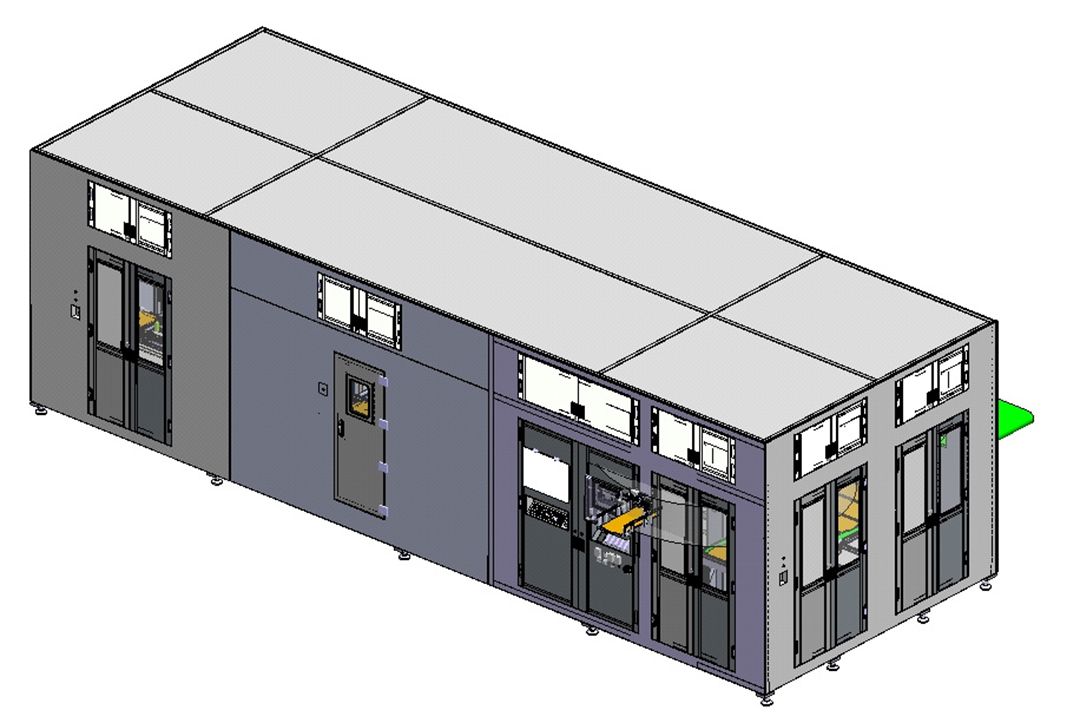

X-ray four-station rotary table machine

Two sets of imaging systems and two sets of manipulators are used for online detection and analysis. It can be used for fully automatic online detection of square polymer pouch cells or finished batteries. Via X-ray generator, this equipment will emit X-ray, which will penetrate the battery inside and be received by the imaging system for imaging and image grasp.Then, the image will be processed by the independently developed software and algorithm, and through automatic measurement and judgment, conforming and non-conforming products can be determined and non-conforming products will be picked out. Front and back ends of equipment can be docked with the production line.

-

Semi-automatic offline imager

Via X-ray source, this equipment will emit X-ray, which will penetrate the battery inside and be received by the imaging system for imaging and image grasp. Then, the image will be processed by the independently developed software and algorithm, and through automatic measurement and judgment, conforming and non-conforming products can be determined and non-conforming products will be picked out.

-

X-Ray Offline CT Battery Inspection Machine

Advantages of equipment:

- 3D imaging. Though section view, the overhang of cell’s length direction and width direction can be detected directly. Detection results will not be affected by electrode chamfer or bend, tab or ceramic edge of cathode.

- Not affected by cone beam, section image is uniform and clear; cathode and anode are clearly distinguished; the algorithm has high detection ac

-

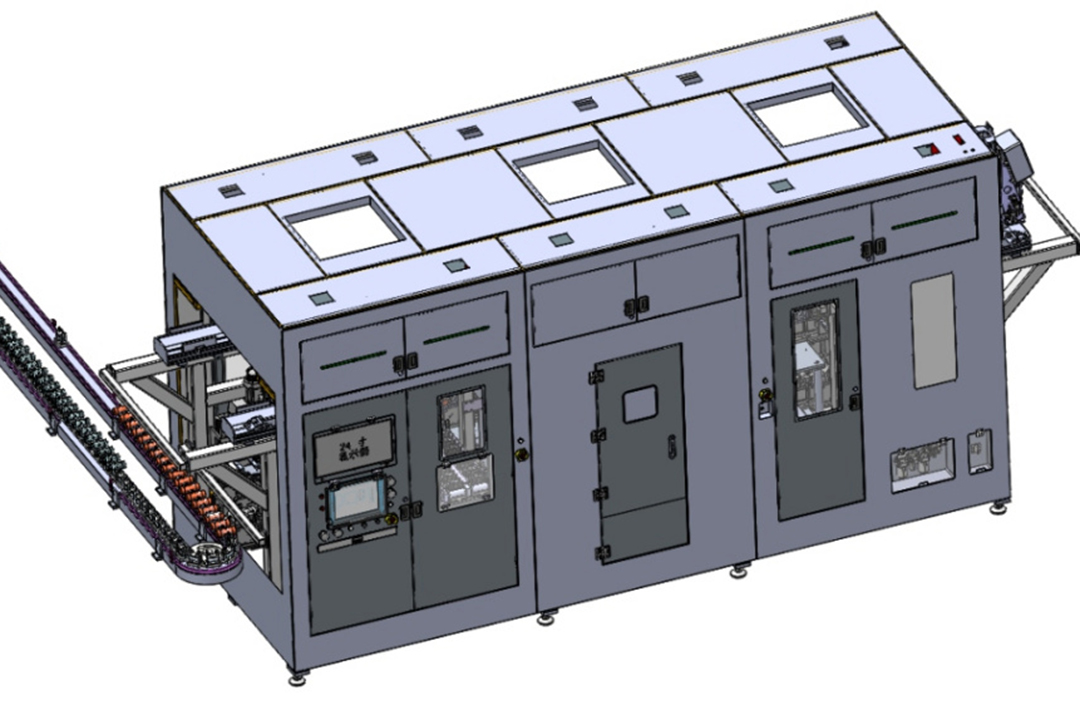

X-ray online winding battery tester

This equipment is connected with the upstream conveying line. It can take cells automatically, place them into equipment for internal loop detection, realize automatic sorting of NG cells, take 0k cells out and place them onto the conveying line automatically and feed into the downstream equipment, so as to realize fully-automatic detection.

-

X-ray online laminated battery tester

This equipment is connected with the upstream conveying line, It can take cells automatically, place them into equipment for internal loop detection, realize automatic sorting of NG cells, take OK cells out and place them onto the conveying line automatically and feed into the downstream equipment, so as to realize fully-automatic detection.

-

X-ray online cylindrical battery tester

Via X-ray source, this equipment will emit X-ray, which will penetrate the battery inside and be received by the imaging system for imaging and image grasp. Then, the image will be processed by the independently developed software and algorithm, and through automatic measurement and judgment, conforming and non-conforming products can be determined and non-conforming products will be picked out Front and back ends of equipment can be docked with the production line.