Products

-

Optical interference thickness gauge

Measure optical film coating, solar wafer, ultra-thin glass, adhesive tape, Mylar film, OCA optical adhesive, and photoresist etc.

-

Infrared thickness gauge

Measure moisture content, coating quantity, film and hot melt adhesive thickness.

When used in the gluing process, this equipment can be placed behind the gluing tank and in front of the oven, for online measurement of gluing thickness. When used in the papermaking process, this equipment can be placed behind the oven for on-line measurement of moisture content of dry paper.

-

测量仪.png)

X-ray online thickness (gram weight) gauge

It is used for thickness or gram weight detection of film, sheet, artificial leather, rubber sheet, aluminum & copper foils,steel tape, non-woven fabrics, dip coated and such products.

-

Cell seal edge thickness gauge

Thickness gauge for cell seal edge

It is placed inside the top-side sealing workshop for pouch cell and used for offline sampling inspection of seal edge thickness and indirect judgment of sealing quality.

-

测量仪.png)

-

Multi-frame synchronized tracking & measuring system

It is used for cathode & anode coating of lithium battery. Use a multiple of scanning frames for synchronized tracking & measurement of electrodes.

The multi-frame measuring system is to constitute the single scanning frames with same or different functions into a measuring system by making of the distinctive tracking technology, so as to realize all functions of single scanning frames as well as synchronized tracking & measuring functions that cannot be achieved by single scanning frames. According to the technological requirements for coating, scanning frames can be chosen and 5 scanning frames are supported at the most.

Common models: double-frame, three-frame and five-frame β-/X-ray synchronous surface density measuring instruments: X-/β-ray double-frame, three-frame and five-frame synchronized CDM integrated thickness & surface density measuring equipment.

-

Five-frame synchronized tracking & measuring system

Five scanning frames can realize synchronous tracking measurement for electrodes. This system is available for wet film net coating quantity, small feature measurement and etc.

-

Super X-Ray Areal Density Measurement Gauge

Measurement adaptable to more than 1600 mm width of coating. Support ultra-high speed scanning.

Small features such as thinning areas, scratches, ceramic edges can be detected.

-

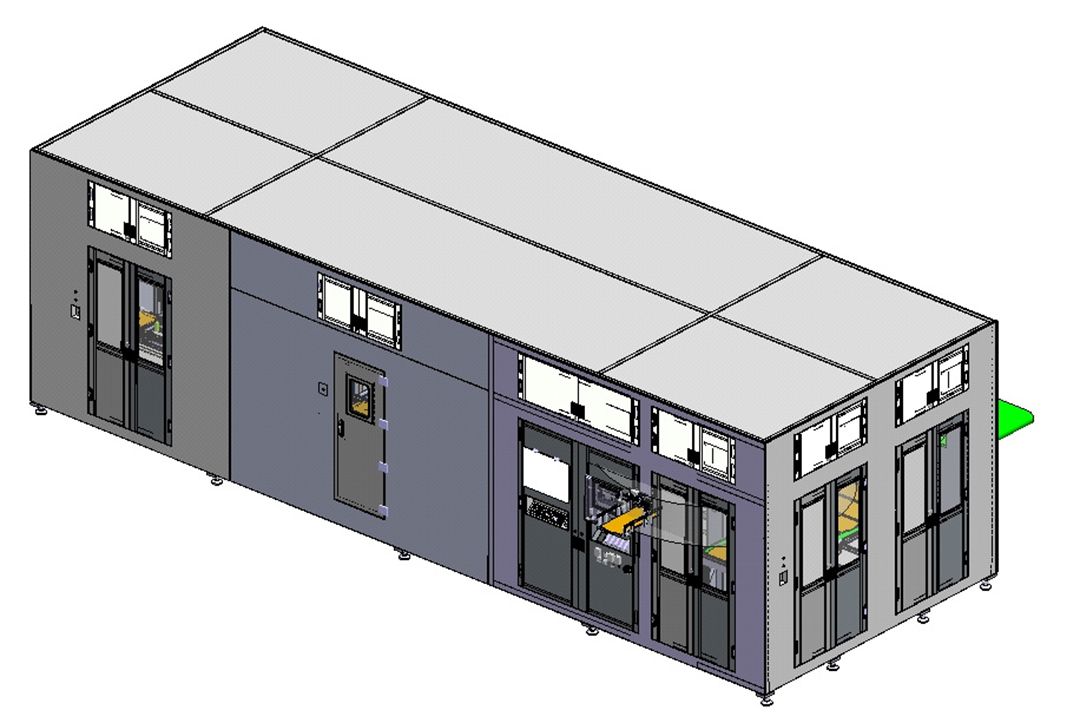

X-ray online winding battery tester

This equipment is connected with the upstream conveying line. It can take cells automatically, place them into equipment for internal loop detection, realize automatic sorting of NG cells, take 0k cells out and place them onto the conveying line automatically and feed into the downstream equipment, so as to realize fully-automatic detection.

-

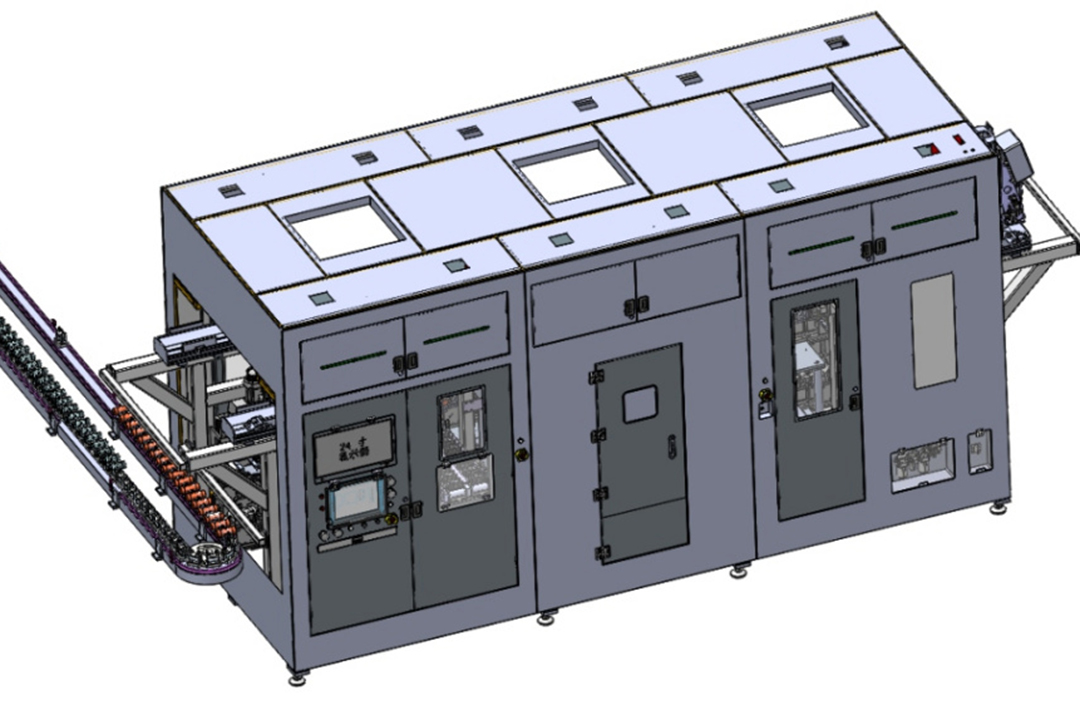

X-ray online laminated battery tester

This equipment is connected with the upstream conveying line, It can take cells automatically, place them into equipment for internal loop detection, realize automatic sorting of NG cells, take OK cells out and place them onto the conveying line automatically and feed into the downstream equipment, so as to realize fully-automatic detection.

-

X-ray online cylindrical battery tester

Via X-ray source, this equipment will emit X-ray, which will penetrate the battery inside and be received by the imaging system for imaging and image grasp. Then, the image will be processed by the independently developed software and algorithm, and through automatic measurement and judgment, conforming and non-conforming products can be determined and non-conforming products will be picked out Front and back ends of equipment can be docked with the production line.