Products

-

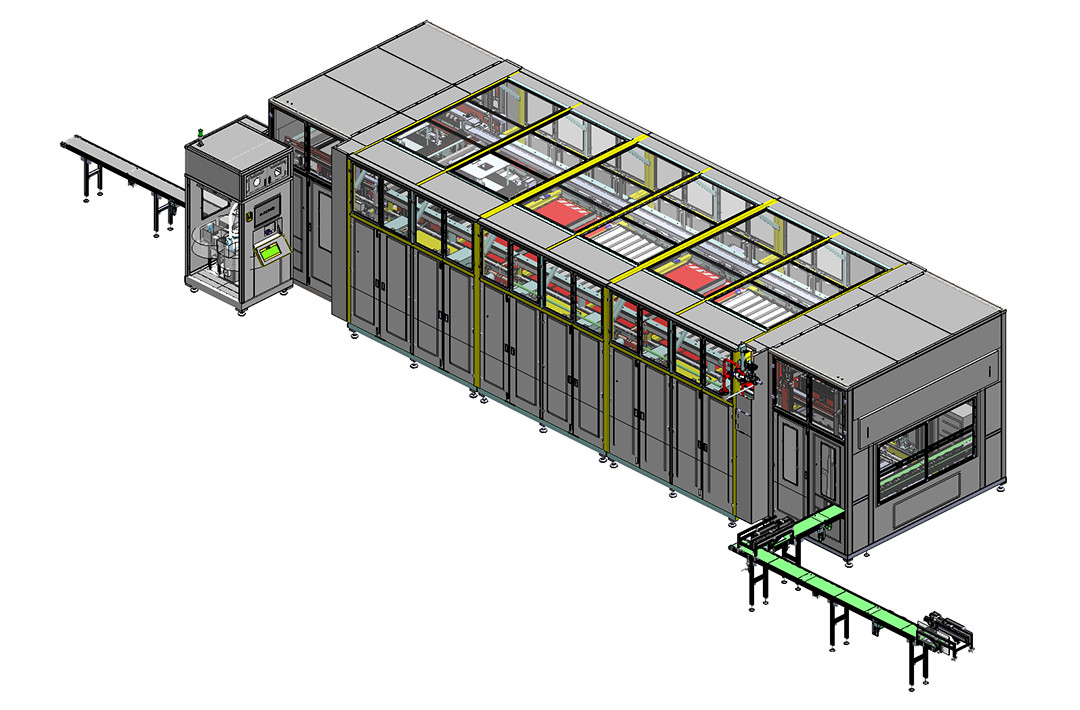

Fully automatic high-temperature standing & aging furnace

Fully automatic high-temperature aging of battery after electrolyte injection

Improve battery capacity consistency (temperature consistency makes electrolyte be fully infiltrated)

Improve high-temperature standing efficiency, decreased from 24 hours to 6 hours

Battery aging data is traceable.

-

X-Ray Offline CT Battery Inspection Machine

Advantages of equipment:

- 3D imaging. Though section view, the overhang of cell’s length direction and width direction can be detected directly. Detection results will not be affected by electrode chamfer or bend, tab or ceramic edge of cathode.

- Not affected by cone beam, section image is uniform and clear; cathode and anode are clearly distinguished; the algorithm has high detection ac

-

CDM integrated thickness & areal density gauge

Coating process: on-line detection of small features of electrode; common small features of electrode: holiday starving (no leakage of current collector, small gray difference with normal coating area, failure of CCD identification), scratch, thickness contour of thinning area, AT9 thickness detection etc.

-

Laser thickness gauge

Electrode thickness measurement in the coating or rolling process of lithium battery.

-

X-/β-ray areal density gauge

Conduct on-line non-destructive testing on the surface density of the measured object in the coating process of lithium battery electrode and the ceramic coating process of separator.

-

Offline thickness & dimension gauge

This equipment is used for electrode thickness and dimension measurement in the coating, rolling or other processes of lithium battery, and can improve the efficiency and consistency for first and last article measurement in the coating process and offer a reliable and convenient method for electrode quality control.

-

3D profilometer

This equipment is mainly used for lithium battery tab welding, auto parts, 3C electronic parts and 3C overall testing etc, and is a kind of high-precision measuring equipment and can facilitate measurement.

-

Film flatness gauge

Test the tension evenness for foil and separator materials, and help customers understand whether the tension of various film materials is consistent by measuring the wave edge and roll-off degree of film materials.

-

X-ray four-station rotary table machine

Two sets of imaging systems and two sets of manipulators are used for online detection and analysis. It can be used for fully automatic online detection of square polymer pouch cells or finished batteries. Via X-ray generator, this equipment will emit X-ray, which will penetrate the battery inside and be received by the imaging system for imaging and image grasp.Then, the image will be processed by the independently developed software and algorithm, and through automatic measurement and judgment, conforming and non-conforming products can be determined and non-conforming products will be picked out. Front and back ends of equipment can be docked with the production line.

-

Semi-automatic offline imager

Via X-ray source, this equipment will emit X-ray, which will penetrate the battery inside and be received by the imaging system for imaging and image grasp. Then, the image will be processed by the independently developed software and algorithm, and through automatic measurement and judgment, conforming and non-conforming products can be determined and non-conforming products will be picked out.

-

Vacuum baking monomer furnace series

Each chamber of monomer furnace can be heated and vacuumized separately to bake the battery and operation of each chamber does not affect each other, Flow of fixture trolley for RGV dispatching and carrying battery between chamber and loading/ unloading can realize on-line battery baking. This equipment is divided into five parts, feeding group tray, RGV dispatching system, vacuum baking, unloading & dismantling tray cooling, maintenance & caching.

-

Vacuum baking tunnel furnace series

Tunnel furnace chamber is arranged in a tunnel type, with compact structure layout, The whole machine includes heating trolley, chamber (atmospheric pressure + vacuum), plate valve (atmospheric pressure + vacuum), ferry line (RGV),maintenance station, loader/ unloader, pipeline and logistics line (tape).