FEATURED

MACHINES

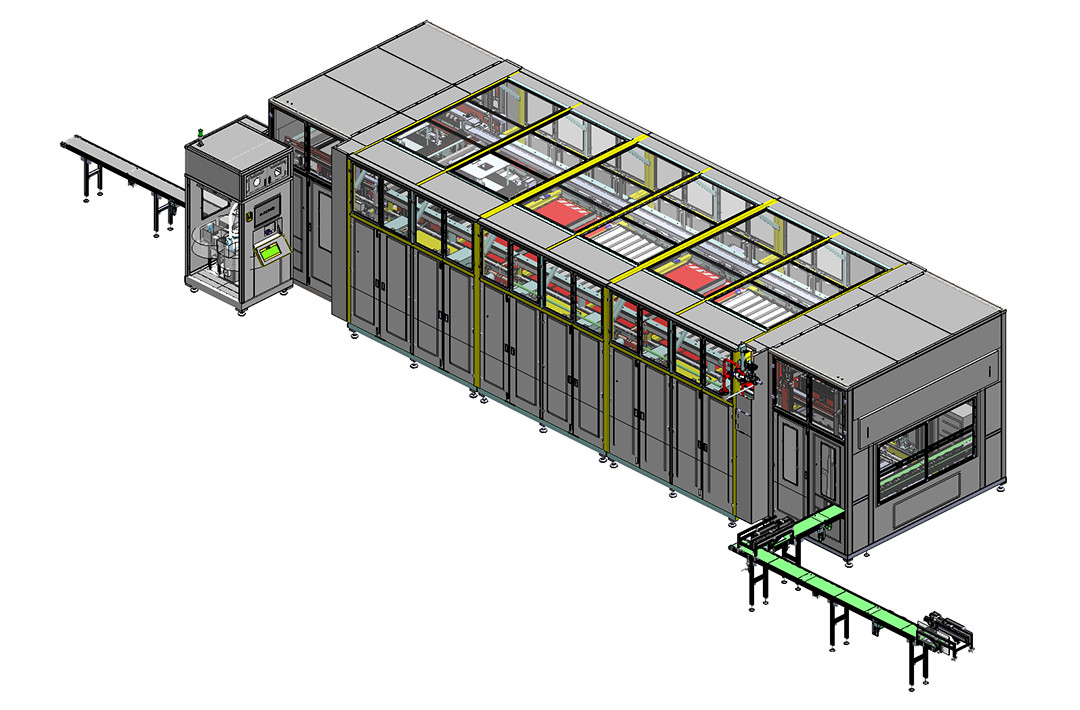

Vacuum baking monomer oven

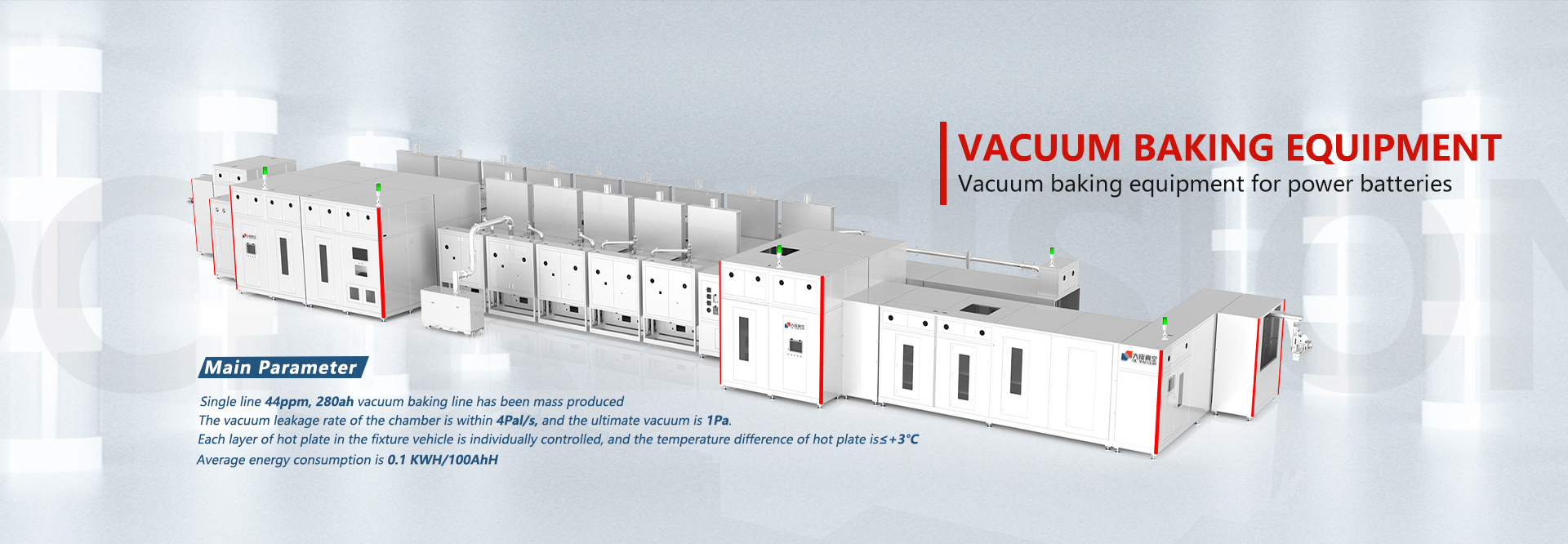

Single machine 40ppm+ capacity potential

Average energy consumption is 0.1KWH/100AnH

Vacuum leak rate of chamber is within 4PaL/s, and ultimate vacuum is 1Pa

Modular design, on-site installation and commissioning within 15 days

METHODS MACHINE TOOLS CAN PARTNER

LITHIUM BATTERY PRODUCTION & MEASURING EQUIPMENT SOLUTION PROVIDER.

● Lithium battery electrode measuring equipment

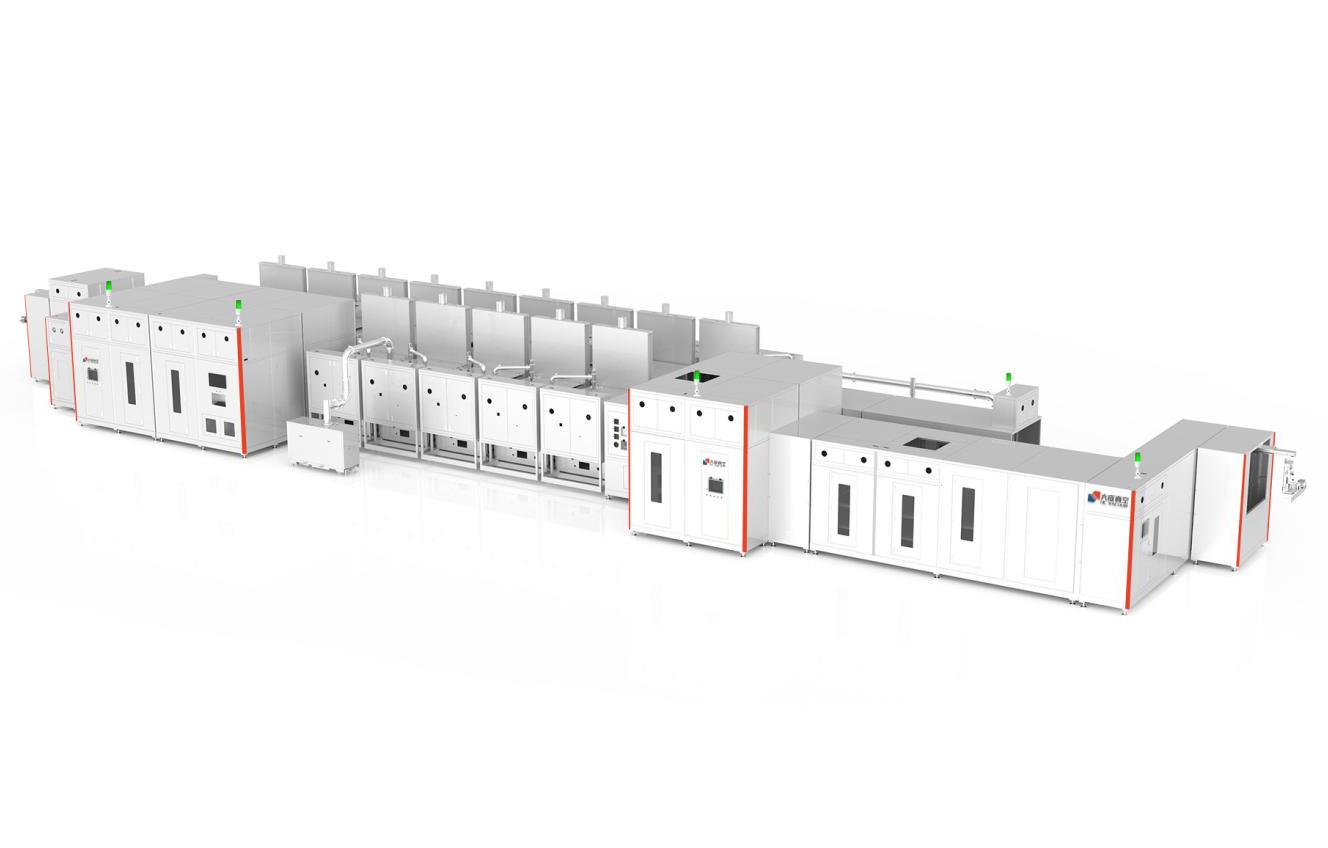

● Vacuum baking equipment

● X-Ray imaging detection equipment

-

0+ Employees 1100+

Staff aty.: 1100 staff, 20% of them are research staff. -

0+ R&D personnel 230+

230 R&D personnel integrated with machinery, electricity and software. -

0+ Patent applications 238+

238 patent applications,140 authorized patents, 37invention patents and 56 software Copyrights. -

0+ TOP customers 20+

TOP 20 customers in the battery field are all covered

MISSION

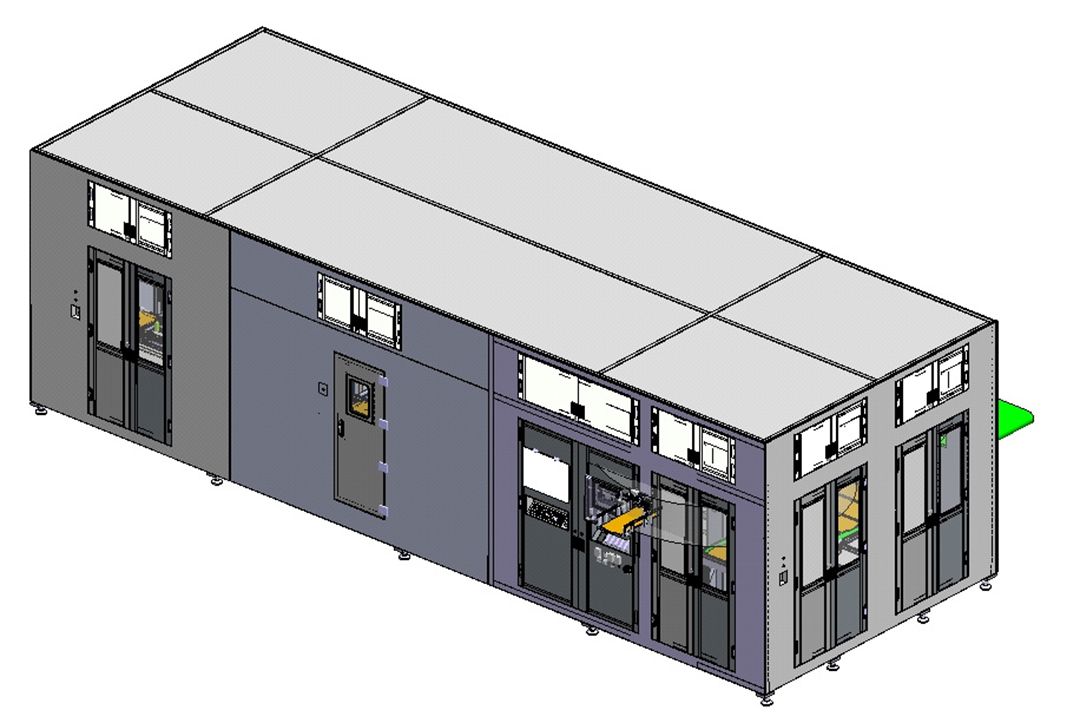

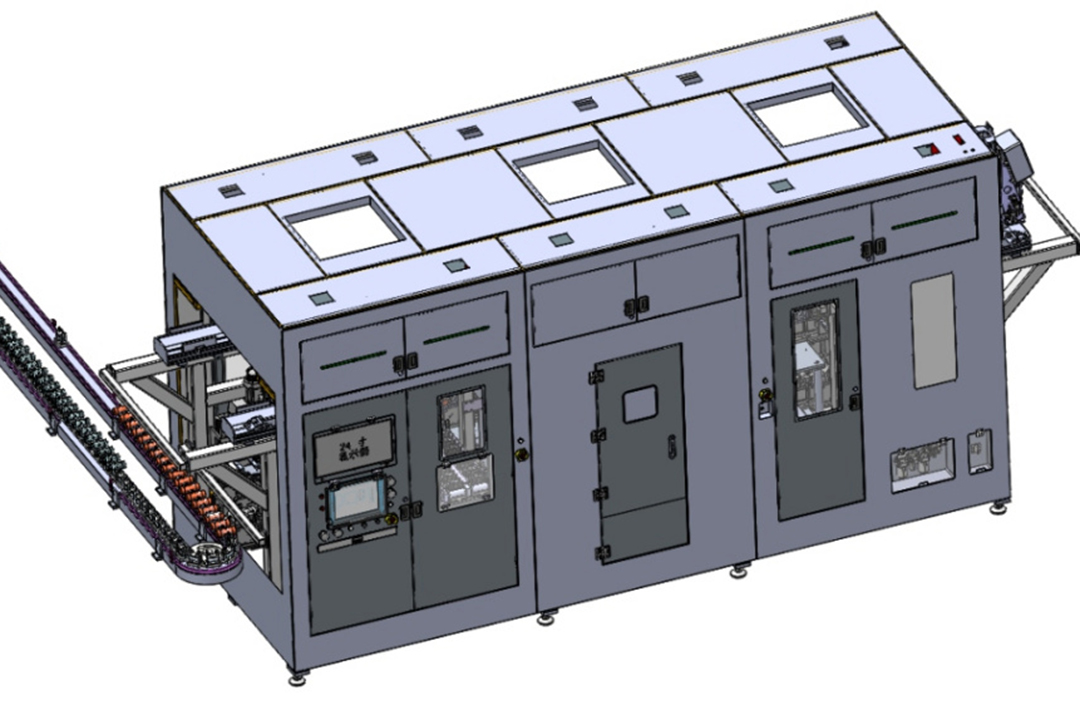

Vacuum drying monomer furnace series

Each chamber of monomer furnace can be heated and vacuumized separately to bake the battery and operation of each chamber does not affect each other. Flow of fixture trolley forRGV dispatching and carrying battery between chamber and loading/ unloading can realize on-line battery baking. This equipment is divided into five parts, feeding group tray, RGV dispatching system, vacuum baking, unloading &dismantling tray cooling,maintenance & caching.

recent

NEWS

-

Phone

-

E-mail

-

WeChat

WeChat

-

Top

测量仪.png)